September 26, 2023 - 0 comments

Champagne, the sparkling elixir often synonymous with celebrations and luxury, is the result of meticulous craftsmanship that combines tradition with innovation. The process behind creating this effervescent delight, known as Méthode Champenoise, involves a delicate dance of nature, science, and art. Champagne production adheres to rigorous standards, but many winemakers in the Champagne region also strive to work as naturally as possible, creating magnificent Champagnes while respecting the environment and the inherent complexities of the craft.

In the world of wine, the term "natural" has gained prominence as consumers increasingly value products created with minimal intervention, working their vineyards without synthetic products and practicing minimal intervention winemaking. These upstanding winemakers embrace the challenge of producing Champagne with little to no added sulfur, despite the inherent complexities of the process. However, a few key steps in Champagne production deviate from the widely accepted definition of natural wine.

Champagne production begins with the manual harvest of grapes at the end of summer, as mandated by the AOC Champagne specifications. After harvest, the grapes are gently pressed to extract the juice, which forms the foundation for Champagne.

The next stages involve fermentation. Alcoholic fermentation, where yeasts transform sugars into alcohol. Optionally, Champagne producers can also undertake malolactic fermentation. As with all wines, malolactic fermentation generally follows alcoholic fermentation, although this is not always the case.

After this first fermentation step, Champagne diverges from standard winemaking. In the Champagne region, from January 1st of the year following the harvest, a process called tirage takes place. During tirage, the wine is bottled and blended with a mixture called liqueur de tirage. This blend contains still wine (grape juice obtained through natural alcoholic fermentation), selected yeasts, and sugar. The addition of liqueur de tirage activates what is known as "prise de mousse," the formation of bubbles in Champagne. This step is crucial in creating the iconic effervescence that characterizes Champagne.

As time passes, the bottled Champagne undergoes aging, which is subject to regulations. Non-vintage Champagnes age for at least 15 months, while vintage Champagnes require a minimum of 3 years. During aging, a process called stirring is employed. Bottles are gradually turned from a horizontal position to a "head down" position, allowing the deposit, composed of dead yeast from the second fermentation, to collect in the neck of the bottle.

The final steps of Champagne production involve disgorgement and dosage. The neck of the bottle is submerged in a frigid solution at around -27°C, forming an ice cube that traps the sediment. This process entails opening the bottle to expel the sediment due to the pressure within. The liquid lost during disgorging is replaced with a wine known as "liqueur d'expédition" or "liqueur de dosage." Depending on the wine added, sugar may or may not be introduced. A "zero dosage" Champagne, also called "brut nature," is created when no sugar is added during this step.

While Champagne production adheres to strict regulations, it remains a labor-intensive and intricate process. Winemakers in the Champagne region, despite their commitment to natural winemaking practices, encounter two key stages—tirage and dosage—that deviate from the purist definition of natural wine. These steps are essential to crafting the iconic effervescence that sets Champagne apart. Sadly, if a champagne winemaker wants to experiment, as many natural winemakers do, they might lose their Champagne AOC . If this happens they are forced to give all of their wine to the co-operative distillery and are not able to bottle it under their name, essentially losing the work they’ve done for that year.

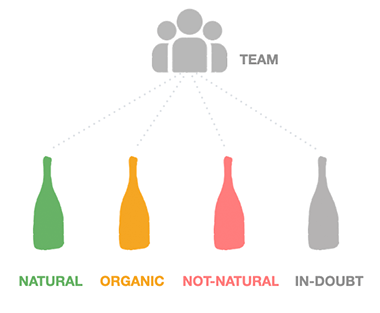

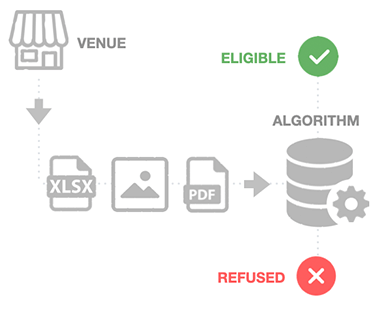

We’d like to take this opportunity to also let you know what we consider to be a ‘natural’ champagne wine maker at Raisin. Here is our criteria:

More than 50% of the wines produced at the domain must meet these criteria:

- Grapes from vineyards free of synthetic products.

- Hand-picked grapes.

- Alcoholic and malolactic fermentation with indigenous yeast only.

- Physical techniques such as reverse osmosis, tangential filtration, flash pasteurization, thermovinification, centrifugation, etc. are not permitted.

- Addition of selected yeasts (non-GMO) is authorized for prise de mousse only.

- The only input accepted is sulfur. Total volume must not exceed 40mg/L after disgorging and dosage.